Introduction

In Microbiology Laboratory, the required material is sterilized either by dry or moist heat, but not every required material can be sterilized with heat. Therefore, the heat sensitive or labile materials are sterilized by membrane filtration method. When heat sensitive materials are exposed to heat, it leads to its denaturation. For example, when Antibiotics and Vitamins are exposed to heat, it causes denaturation of its structure, and hence loses its function. If such denatured antibiotics or vitamins are added to media; it won’t be able to fulfill its role.

To sterilize the heat labile material, it is passed through a membrane filter, which has very small pores (smaller than size of the microorganism) that allows the passage of liquid or gas, but not the microorganism. Commercially, filters with range of pore sizes are available. The bacterial size ranges from 0.3 to 0.5 μm and therefore the filter with 0.2 μm is widely used. As virus and bacterial spores are smaller than 0.2 μm, the membrane filter cannot filter viruses and bacterial spores. For such conditions, the nano size membrane filters are employed. Membrane Filtration is one the best method for sterilizing heat sensitive material as its protects them from denaturation.

Principle:

The membrane filter traps the microbes or contaminants, which are larger than the pore size of the filter. The selection of membrane filter depends upon the size of the contaminant. The membrane of the filters is mostly made from cellulose.

Requirements:

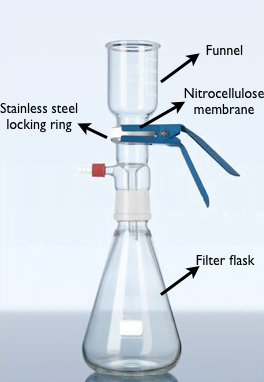

- Membrane filter assembly

- Nitrocellulose filter

- Heat labile material

Method:

- The dilution of required heat labile solution is prepared and kept ready for sterilization

- The Membrane filter assembly is set up

- The forcep is dipped in alcohol and then flame sterilized.

- In sterile condition, sterilized forceps is used to pick the sterile nitrocellulose membrane and then it is kept on the stainless steel stage of membrane filter.

- The funnel part of assembly is fixed by using the locking rings.

- The desired prepared dilution of heat labile material is poured in the funnel of the membrane filter assembly.

- The filtrate that we obtain is sterile and ready for use.

- The funnel is unlocked and by using the sterile forcep, the nitrocellulose membrane is picked and can be placed on the petri plate containing nutrient media. After the incubation, the colonies can be observed on the petri plate.

Result:

The heat labile material is sterilized by using Membrane filter.

Conclusion:

The heat labile material is sterilized and ready for use. The used Membrane filter when incubated on nutrient media, bacterial colonies were observed.

Need more help? Click here.

If you liked this resource, please Like, Share, and Subscribe us for more content.