The Principle and Construction of Autoclave has been the most searched query ever since the pandemic hit. A lot of students and lab professionals have been looking to have a quick read on. The following article provides the much-desired easy-read theory

Introduction of Autoclave:

Autoclave is an equipment used for sterilization. Sterilization means inhibition or killing of microbes like bacteria, spores, fungi and virus etc. Hence in Microbiology and Biotechnology, the autoclave is used for sterilization of media and glasswares etc. In autoclave, the method of killing the microbe is by usage of moist heat and pressure. The Autoclave design and principle is referred from pressure cooker. The Autoclave is one of the most used equipment for sterilization in educational lab institutes, research institutes and pharmaceutical companies.

The Autoclave was designed and invented by Charles Chamberland in the year 1879. The autoclaves now that are commercially available are with better monitoring and safety system and works on the same original principle.

Principle of Autoclave:

Autoclave works on the principle of steam under pressure. The high temperature and pressure ensures killing of microorganisms like virus, fungi, bacteria and heat resistant, spores. The high temperature and moist heat coagulate and denature microbial proteins and enzymes. The Autoclave is usually set at 121°C and 15 lbs pressure for 15 minutes.

Steps in Autoclave cycle-

- Boiling phase: The electric heat causes boiling of water and generate the steam. The produced steam replaces the trapped air by displacement.

- Rising temperature phase: The temperature rises and reaches up to the set level i.e. 121°C.

- Sterilization time: This is the time when microbes are killed.

- Release the pressure: The entrapped pressure is released by opening the valve.

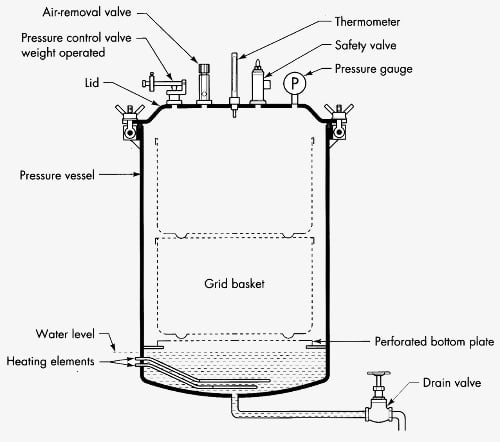

Construction of Autoclave (Structure of Autoclave)

The autoclave is made of following components-

- Vessel or pressure chamber

- Lid or door

- Pressure gauge

- Pressure releasing unit (whistle)

- Safety valve

- Electrical heater

1. Vessel/Pressure chamber –

The vessel is made from stainless steel. The inner chamber is protected by outer jacket. The inner chamber is the place where we keep the autoclavable material for sterilization. The size of the chamber varies and selected based on the motive of use.

2. Lid/Door –

The Vessel mouth is covered by lid or door. It is also made from stainless steel. The lid allows trapping and retaining the heat and pressure inside the chamber and producing favorable environment for sterilization. The lid is tightly closed with the help of airtight screw.

3. Pressure Gauge –

It is present on the upper surface of lid. Its function is to indicate the level of pressure that is produced during autoclaving. It is vital part because it allows us to visually see the rise of pressure and alert for any forthcoming mishap hence it ensures the safety.

4. Pressure releasing unit/whistle –

The whistle is placed on top of the surface of the lid, just like pressure cooker. The whistle allows us to release the pressure whenever required.

5. Safety Valve:

It is present on the surface of the lid. Their function is to avoid catastrophic accident especially when pressure inside the chamber is uncontrollable.

6. Heater –

The electric heater is placed beneath the chamber. The electric heater working principle is similar to geezer. The electric heater start heating it causes boiling of water. The user need to maintained the water level as per the marking. Less water may cause burning and more water may lead to enter water in the experimental material.

Applications:

It is used for sterilization of media, glasswares, solutions and heat resistant numerous laboratory accessories. It is also used to decontaminate the media before discarding.

We hope that this article has helped to clear the Principle and Structure of Autoclave.

References:

https://www.cdc.gov/infectioncontrol/guidelines/disinfection/sterilization/steam.html

http://www.frankshospitalworkshop.com/equipment/autoclaves_equipment.html

https://www.explainthatstuff.com/autoclaves.html

https://ehs.princeton.edu/book/export/html/380

https://labsafety.gwu.edu/autoclave-safety

Cappucino JG and Sherman N (1996). Microbiology, A Laboratory Manual 4th edition. Benjamin Cumings Inc. California.

https://tuttnauer.com/blog/autoclave-sterilization/what-is-an-autoclave

If you liked this resource, please Like, Share, and Subscribe us for more content.

Dr. Sangha Bijekar has 9 years of Teaching Experience at University level. She loves to get engage in teaching and learning process. She is into blogging from last two years. She intends to provide student friendly reading material. She is avid Dog Lover and animal rescuer. She is learned Bharatnatyam and Katthak Dancer. She is into biking and She also loves to cook.